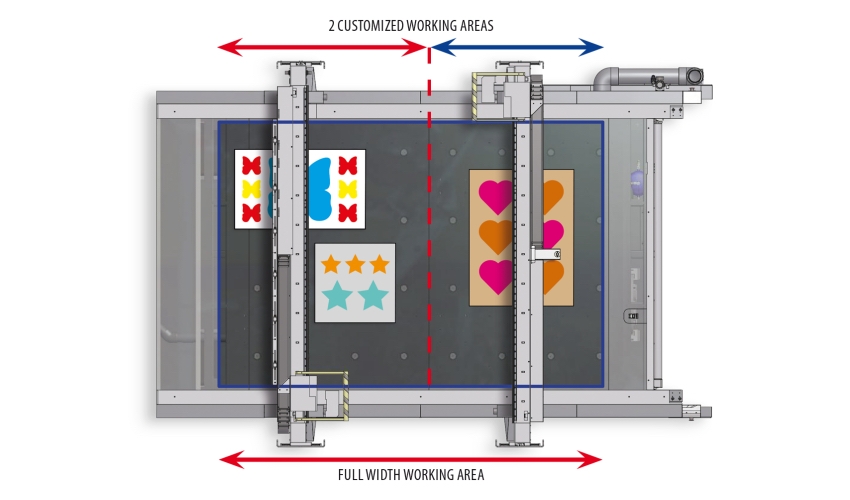

Elitron Kombo TH Cut two different jobs at once! Twin independent gantries for incredible cutting performance and productivity. Simple to use, as automated as you want it and built to a quality that we thought long gone. The new generation twin gantry, twin head cutter.  Each head can operate independently and have the same or different cutters. the Elitron software works out the best tools to use and the best workflow automatically! Llike having two cutters in one advanced 3100 x 2000mm bed size. Each cutting head is equipped with different tools: blade, creasing wheel, probe tool (to determine material height), pen module and laser pointer. Thanks to Elitron  ’s Twin Cut software, the workload of the job in ’s Twin Cut software, the workload of the job in hand is automatically distributed between both cutting heads thus optimising the production yield and considerably reducing production times. Kombo TH is great for PVC Boards, Foamex, Correx, cardboard, corrugated cardboard, lightweight card, plastic materials, honeycomb materials, graphic boards, and many more Suction Surface.  The working area is equipped with a powerful multi sectioned vacuum system that allows to focus the power only where it's needed. No blanking off, no excess noise. Automatic Nesting Elitron Sofware can automatically arrange the images for a given size of sheet, or detected by the Seeker Pro and make the most economical use of the materials on the bed.Projection System Maximises the yield from your materials by projecting images onto the media beneath. The operator can then seee exactly how to plan the use of leftovers, half sheets etc. The material can then be used accordingly. For instance we know of an Elitron customer who uses left over PVC for interior van linings for a van hire company and can project the profile of each component of the lining onto the sheets, arrange them to suit and then cut them out without moving them from their arrangement. Simple and profitable Virtual Die Projection System:

The ultimate in operational simplicity adopted by Elitron in all its cutting systems with “virtual dies”. the operator uses a simple and effective projection system to easily position the shapes to be cut directly on the material, even on small leftovers or scraps, optimising the performance and thus reducing wastage. Nesting can be done automatically or manually by the operator, using the mouse.

Elitron's software is very intuitive and allows the operator to run a simulation or pre-flight of the proposed cut, here they can see any over or under cuts or in the case of routing, ensure they are using the correct diameter bit. Seeker System The Seeker System comes in two versions, Standard and Pro.The Standard version is fitted to the all the Kombo Range and sees the reference points on the sheet, locates the reference points for the images but does not load the cutting profiles.The Seeker Professional version does this too but also looks at each image individually allowing for distortion caused by the overhead camera position then loads the profile and cutting information for each image. So with the Pro you could put Forex, banner, Dibond all together on the bed and the images would be recognised, the correct cutting profile loaded, the correct tools chosen for each job and the Kombo would then proceed with the cutting.  The Kombo can be fitted with a range of tools such as, oscillating knife, electric or pneumatic, creasing wheels and a range of routing / milling tools. The system has a pre setting function for automatic set up   Twin cutting heads Seeker System |

-

Consumables

-

Sun Protection

- Curtain Production

- Matic M21 Cutting Machine

- EOS Curtain sewing automation

- SEWING-Matic Nyx Overlock sewing system

- SEWING-Matic NYX Ultimate Curtain Sewing System

- SEWING-Matic Nyx Compact

- SEWING- Matic Nyx Top Tape

- SEWING-Matic Nyx Roman

- CUTTING- Matic Olympo Curtains

- CUTTING- Matic Helios Plus Laser

- CUTTING- Matic Flexicut Linear Cutter

- IRONING-Aura Ironing System

- HANDLING-Matic Inspector

- CUTTING-Matic Sonomatic

- STORAGE Matic Atlas H

- Plastgrommet Curtain Station

- Olympo Curtain Inspection

- Printers

-

Roll Cut

-

Cutting

- Digital

- Elitron Spark C

- Elitron Spark F

- Elitron Kombo SD+

- Elitron Kombo TH

- Elitron Kombo SDC+ 3.2

- Elitron Klick Print Management Software

- Elitron Seeker System explained

- Elitron Custom Cutting details

- Matic Flexicut

- Flexa Miura

- Flexa Miura Plus

- Flexa Miura Plus HD

- Flexa Miura II 1650 Wallpaper

- Flexa Extrim

- Flexa Katana

-

Laminators

- CWT Applicator Tables

- OUR GUIDE TO Buying a CWT Flatbed Applicator, Lamination Table or Sign Applicator

- CWT ADVANTAGE FLATBED APPLICATOR TABLE

- CWT REGULAR FLATBED APPLICATOR TABLE

- CWT PREMIUM FLATBED APPLICATOR TABLE

- CWT Linear Cutter

- CWT Linear Cutter Pro

- Traffic Signs

- Cutting Mat Clear Blue Frosted

- Cutting Mat Clear Blue Standard

- Cutting Mat Anti-Static

- CWT Original Cutting Mats

-

Finishing

- Eyelet Machines

- Hand Presses for Eyelets

- Plastrommet Semi-automatic Queen & SpeedQueen

- Plastgrommet Crossover

- Plastgrommet Evolution Automatic eyeleter

- Plastgrommet Autocross Automatic

- Plastgrommet Multipress Automatic

- Plastgrommet Finishing Station

- Plastgrommet Roll to Roll Range

- Plastgrommet All in One

- Plastgrommet Clear Plastic Recyclable Eyelets

- Forsstrom HF eyelet

- Sewing Machines

- Matic CRONOS GO

- Matic CRONOS SEWING SYSTEM

- Matic CRONOS 4.0

- Matic Nyx Overlock

- Matic Nyx Ultimate Curtain Sewing System

- Matic ORION SEWING SYSTEM

- Matic Hercules Awning Sewing System

- Matic Nyx Compact

- Matic Nyx Top Tape Sewing System

- Matic Nyx Roman

- Recyclable Thread

- Recyclable Keder SRK

- Cotton Cones Dual purpose

- Cotton bonded nylon

- White Keder

- Translucent Blue Keder

- Self Adhesive Recyclable

- Silicon Keder

- Hammer In Keder Silver

- Hammer in Keder Clear

-

Racks & Lifters

- Plastgrommet Media Handling

- PLASTGrommet Bull Rack 1620

- Plastgrommet BullRack MAX

- PLASTGrommet BullRack Cutter

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- PLASTgrommet Roll Clips

- PLASTGrommet Compact Lifter

- PLASTGrommet Compact e- Lifter Lite

- PLASTgommet e-lifter Pro

- PlastGrommet RollMax Lifter

- PlastGrommet RollMax e- lifter

- Used & Ex-Dem

- FESPA 2025 Partners