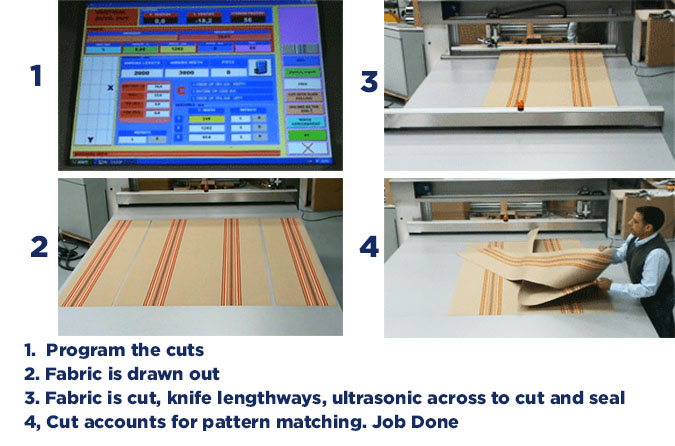

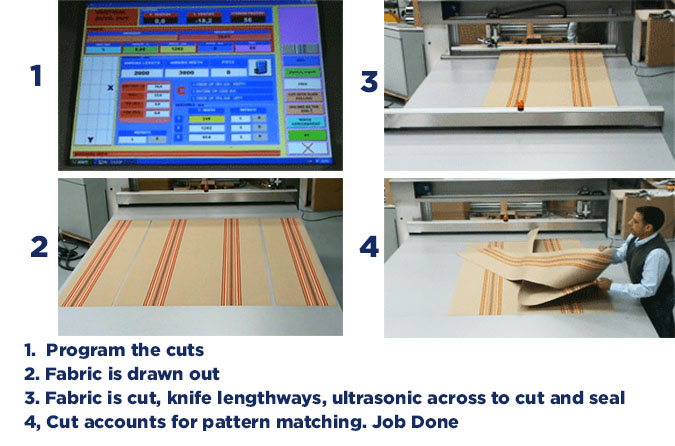

The design and ease of use make the M2 one of the best selling machines in the awning market. Automatic calculation of the cuts takes into consideration the repeat of the stripe pattern, including assymetric stripes, and makes accurate final cut dimensions.

The transverse cut is made by rotary knife since this is the dimension that will be hemmed. The longitudinal cut is made by Ultrasonic knife since this will not be hemmed, the Ultrasonic cutting prevents fraying of the unworked edges.

TECHNICAL SPECIFICATIONS

- Automatic XY cutting

- Useful transversal cut: 1650 mm (42")**

- Useful longitudinal cut: 8000mm (26ft)**

- Working height: 970mm (38")**

- Longitudinal cutting by ultrasonic and transversal by rotary knife.

- Adjustable cutting speed

- Workflow Program Software included (PTM)

- Cuts: PVC, screens, black-out, acrylic, polyester, coated fabrics, mosquito nets.

- Electrical voltage EU: 220-240V / 50 Hz AC

- Air pressure: 6 bar

- Complies with CE safety regulations

FEATURES

- Automatic fabric feeding for a continuous cutting process.

- Press bar to avoid movement of the fabric while cutting.

- Intuitive 15" touch screen to control the machine and enter parameters.

- Automatic calculation of the cuts.

- Precise fabric width measurement tool.

- Dynamic "0" point - Fabric can be clamped in any position due to a movable point of origin for the cut.

- Remote maintenance for troubleshooting

- Capacity of working from fabric waste

- The software can control your inventory - from your stock and from the under table storage carousel.

- Integrated horizontal roll warehouse to optimize space and increase cutting efficiency*

- Bar code or QR code reader*

- Software for sending orders via network*

- Roll up device to roll cut pieces for fast clearing of the cutting surface, and to ease the handling to the next part of the process.*

ADVANTAGES

- Precise and perfectly squared cuts

- High production capacity

- Automatic XY cutting eliminates the need for operator's involvement and handling of the fabric during the cutting process.

- Cut fabric can be positioned anywhere on the table to make the working process more efficient.

- Less fabric waste - The machine can work from fabric waste to make samples, smaller items, etc.

- Doesn't make a lot of noise while cutting or when handling the fabric.

- The software will control your inventory and deduct cut fabrics from the rolls so your stock is always balanced and accurate.

- The under table storage carousel will help speed the efficiency of the machine by eliminating the transport of rolls. They are always close to the operator.

The roll up device will also help increase the production process' speed by helping the operator clear the surface of cut pieces. These will be easier to transport to the next step of the operation.* Optional

** Precise measures are calculated by metric. Imperial may vary a little.