Machine for inspecting, measuring, winding and cutting fabric rolls.

Fabric inspection, measuring, cutting and packing machine. inspect before print, package onto cardboard rolls after processing. massive time saver. Optional bar code printer and reader for complete automation.

An ideal solution to inspection and packing issues. Lengths can be input into the controlls to wind on to a set length and then stop. The built in cutter can then be used to cut the material.

An ideal solution to inspection and packing issues. Lengths can be input into the controlls to wind on to a set length and then stop. The built in cutter can then be used to cut the material.

With the Matic Inspector a single person can examine a full roll quickly for flaws which become obvious when the material is passing over the lightbox. The Inspector can also be located on the output of some of Matic's cutting tables for even more productivity.

The same fast reliable process that unwinds your rolls can also wind them for packing.

• Maximum width of roll: 3200 mm(126 in)

• Inspection surface: 400 mm (15.75 in)

• Maximum diameter of roll: 250 mm (9.875 in)

• Maximum weight of roll: 70 kg (154 lbs)

• Smooth start with adjustable speed control

• Electric rotating cold knife for fast cutting

• Electronic length counter with Metric and Imperial units

• Inspection light on the table

• Speed control

OPTIONAL

• Motorised rear cradle with bi-directional operation

• Inspection table tilted instead of flat

• Increased roll capacity to 600 kg (1320 lbs)

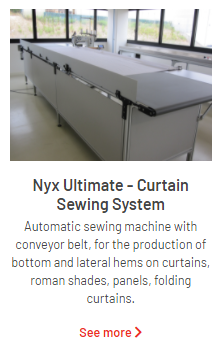

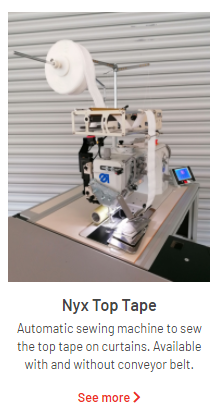

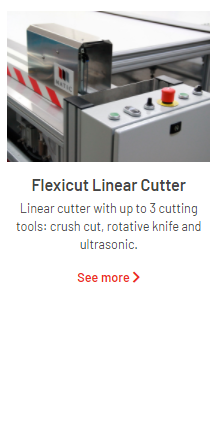

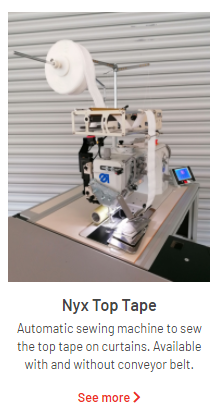

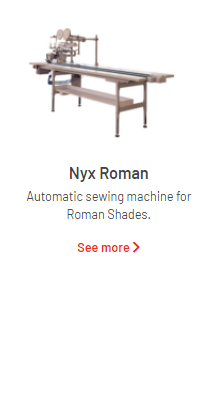

From cutting, ironing, measuring, to final control, we have thought through the the entire production process of traditional curtains, from sewing sides and bottom hems, joining, to applying top tapes and reinforcement, developed a complete solution with focus on automation and easy-to-use.

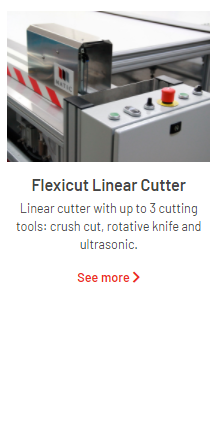

Cutting

.png)

Sewing

Auxiliary Equipment and Accessories

All the completements and accessories you may need for make your workflow smoother: storage, handling, software and accessories.

.png)

.png)

.png)