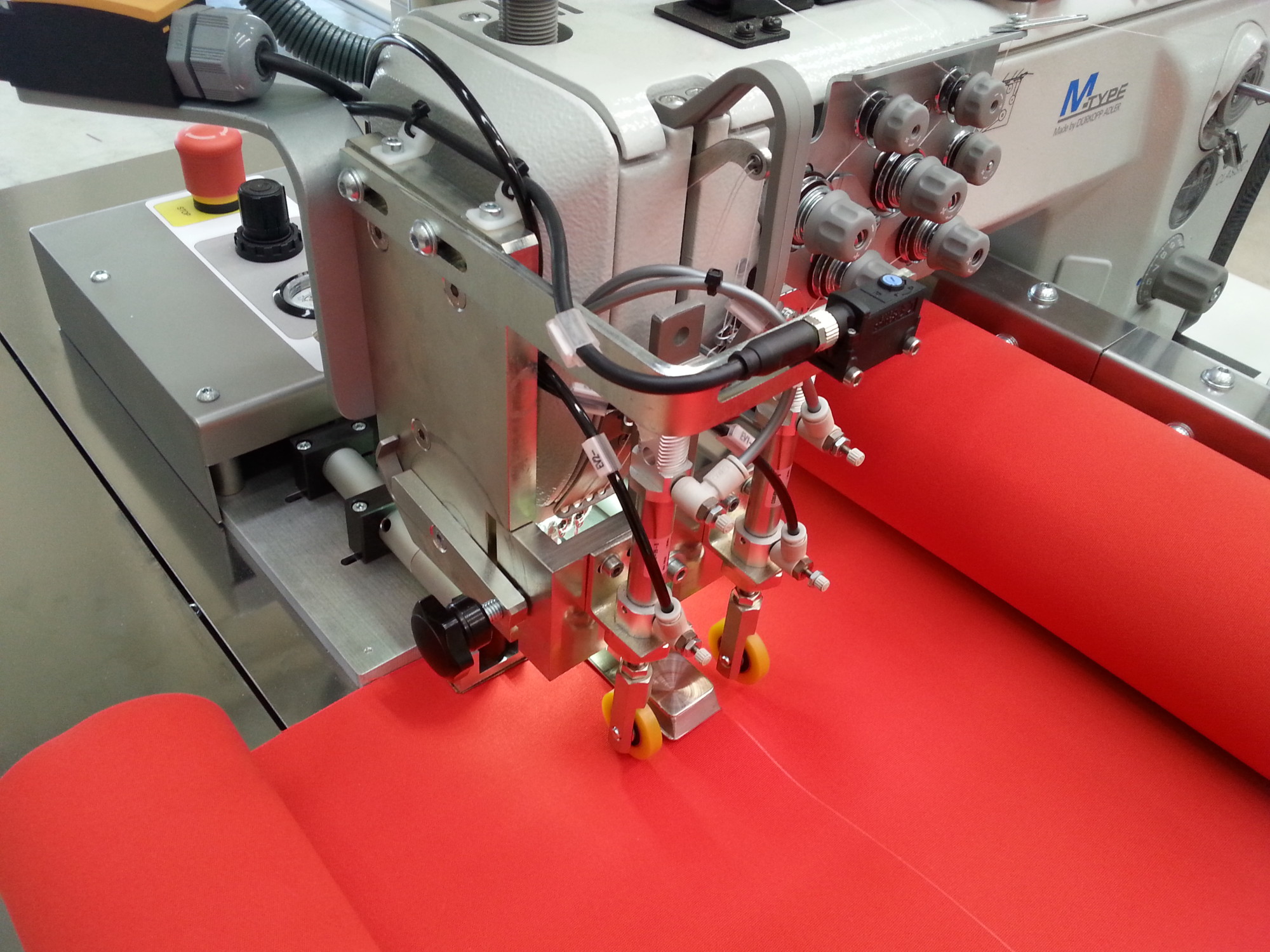

Matic Hercules Moving Head Sewing StationAutomatic unit with moveable sewing head for joining, hemming and inserting the PVC core, skilled operators are not required. Built to last and keep on producing in an industrial environment. For textiles and acrylic or PVC coated fabrics.   TECHINICAL SPECIFICATIONS

Matic Hercules- Sewing Automation with Travelling Head from Atech on Vimeo. |

- Consumables

-

Sun Protection

-

Slitters

-

Cutting

- Elitron

Elitron Graphics Cutters

- Elitron Spark C

- Elitron Spark F

- Elitron Kombo SD+

- Elitron Kombo TH

- Elitron Kombo SDC+ 3.2

- Elitron Custom Cutting details

- Elitron Seeker System explained

- Elitron Klick Print Management Software

Elitron Packaging Cut & Crease

- Elitron Kombo TAV

- Elitron Kombo TAV-R

- Elipack Packaging Design Software

- TAV-R FEFCO Award

- Elitron Reversa Board Turner

Elitron Leather Cutting

- Elitron Booster

- Elitron Elicut Plaza T

- Elitron Dinamo 2T

- Elitron Plaza

- Elitron Visio

- Elitron Kudos

- Elitron Spark F

Elitron Technical Materials Cutter

- Elitron Kombo T

- Laminators

-

Printers

-

Finishing

- Eyelet Machines

- Hand Presses for Eyelets

- Plastrommet Semi-automatic Queen & SpeedQueen

- Plastgrommet Crossover

- Plastgrommet Evolution Automatic eyeleter

- Plastgrommet Autocross Automatic

- Plastgrommet Multipress Automatic

- Plastgrommet Finishing Station

- Plastgrommet Roll to Roll Range

- Plastgrommet All in One

- Plastgrommet TexWiz

- Plastgrommet Clear Plastic Recyclable Eyelets

- Forsstrom HF eyelet

- Sewing Machines

- Matic CRONOS GO

- Matic CRONOS SEWING SYSTEM

- Matic CRONOS 4.0

- Matic Nyx Overlock

- Matic Nyx Ultimate Curtain Sewing System

- Matic ORION SEWING SYSTEM

- Matic Hercules Awning Sewing System

- Matic Nyx Compact

- Matic Nyx Top Tape Sewing System

- Matic Nyx Roman

- Recyclable Thread

- Recyclable Keder SRK

- Cotton Cones Dual purpose

- Cotton bonded nylon

- White Keder

- Translucent Blue Keder

- Self Adhesive Recyclable

- Silicon Keder

- Hammer In Keder Silver

- Hammer in Keder Clear

-

Racks & Lifters

- Plastgrommet Media Handling

- PLASTGrommet Bull Rack 1620

- Plastgrommet BullRack MAX

- PLASTGrommet BullRack Cutter

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- PLASTgrommet Roll Clips

- PLASTGrommet Compact Lifter

- PLASTGrommet Compact e- Lifter Lite

- PLASTgommet e-lifter Pro

- PlastGrommet RollMax Lifter

- PlastGrommet RollMax e- lifter

- PlastGrommet Jumbo Floor Rack

- PlastGrommet Jumbo WallRack

- Used & Ex-Dem

- Case Studies