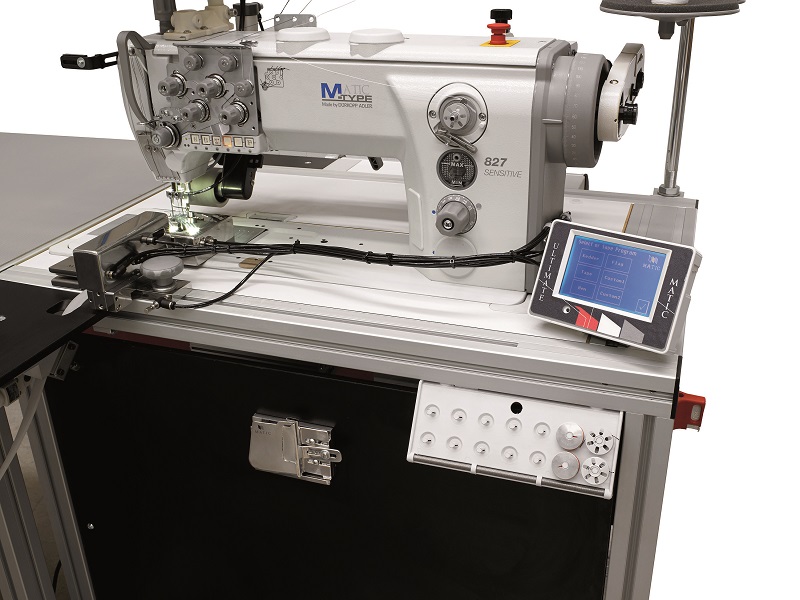

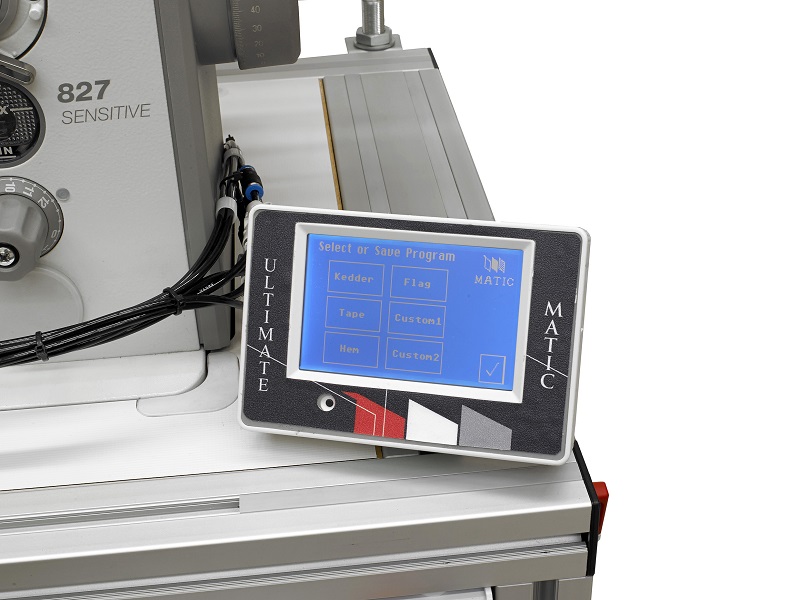

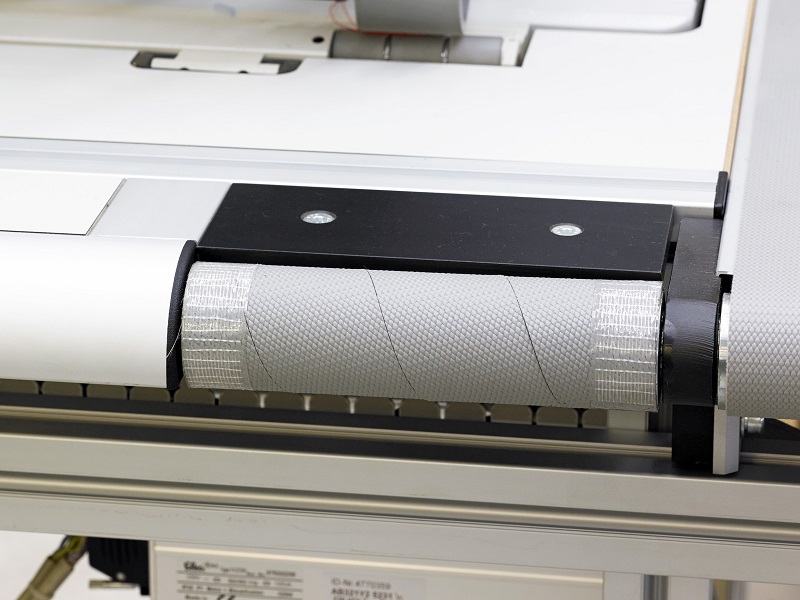

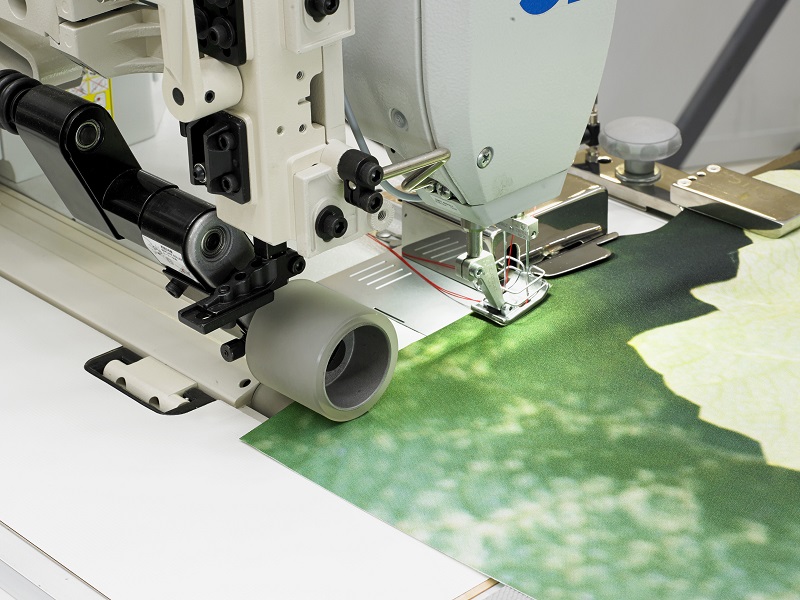

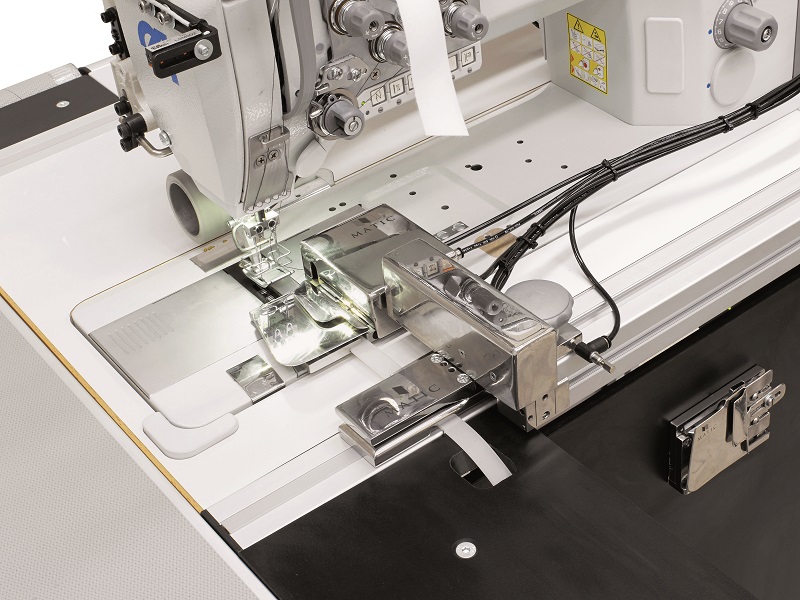

Matic Cronos Modular Sewing StationConveyor belt driven automated sewing machine for the production of silicone edge graphics (SEG), pockets, hems and hook and loop fastener.The Cronos Sewing System is an automated conveyorbelt driven solution for the production of SEG, flags, displays, banners, tents and curtains. It is the highest quality and most flexible solution for sewing textiles.From a Basic solution to the Ultimate model, this machine can be built up with various options and attachments, making it perfect for your production and your budget. The Cronos Sewing System is easy and fast, it will reduce production time and increase your output, without the need of a skilled operator. Achieve high quality flat seams, SEG (keder, spline, gasket), pockets, double-hems, hook and loop fastener and many other sewn applications with the same configuration of machine. The sewing guides will be custom built for your application, making this machine adapt to your current production style. A big solution in a small package. CRONOS utilises only 4m2 (43 ft2) of work space, allowing it to fit in any size workroom. Specifications

**Precise measures are calculated with the metric system. Imperial is given only as a reference.          |

-

Sun Protection

-

Consumables

- Plastgrommet Accessories

- PLASTGrommet Bull Rack 1620

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet BullRack Cutter

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- Swivel Rack

- PLASTGrommet Compact Lifter

- PLASTGrommet Compact e- Lifter Lite

- PLASTGrommet Quick Lifter

- Printers

-

Cutting

-

Laminators

-

Finishing

- Eyelet Machines

- Plastrommet Semi-automatic Queen & SpeedQueen

- Plastgrommet Crossover

- Plastgrommet Evolution Automatic eyeleter

- Plastgrommet Autocross Automatic

- Plastgrommet Multipress Automatic

- Plastgrommet Finishing Station

- Plastgrommet Roll2Roll Lite

- Plastgrommet All in One

- Plastgrommet Clear Plastic Recyclable Eyelets

- Plastgrommet Roll to Roll Pro

- Sewing Machines

- Matic CRONOS GO

- Matic CRONOS SEWING SYSTEM

- Matic CRONOS 4.0

- Matic Nyx Overlock

- Matic Nyx Ultimate Curtain Sewing System

- Matic ORION SEWING SYSTEM

- Matic Hercules Awning Sewing System

- Matic Nyx Compact

- Matic Nyx Top Tape Sewing System

- Matic Nyx Roman

- Recyclable Thread

- Recyclable Keder SRK

- Cotton Cones Dual purpose

- Cotton bonded nylon

- White Keder

- Translucent Blue Keder

- Self Adhesive Recyclable

- Silicon Keder

- Hammer In Keder Silver

- Hammer in Keder Clear

-

Racks & Lifters

- Plastgrommet Media Handling

- PLASTGrommet Compact Lifter

- PLASTGrommet Bull Rack 1620

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet BullRack Cutter

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- PLASTGrommet Compact e- Lifter Lite

- PLASTgommet e-lifter Pro

- PLASTgrommet Roll Clips

- Used & Ex-Dem

- Cutting Mats & Tools