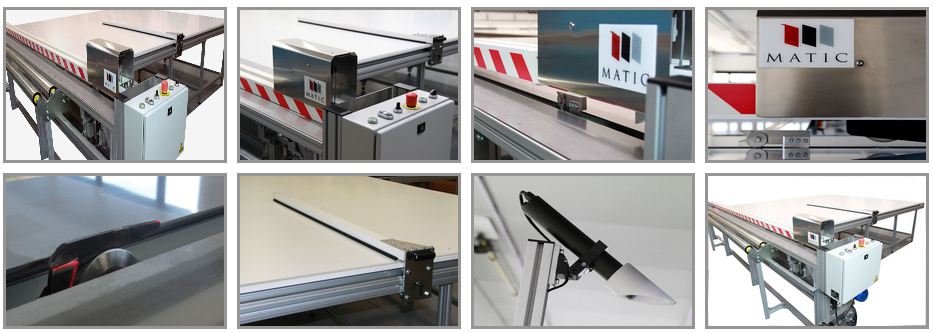

Matic FlexicutThe FLEXICUT is a semi-automatic linear cutter with the versatility of 1 up to 3 cutting tools: Ultrasonic, Crush Cut and Rotating Knife.

|

-

Sun Protection

-

Consumables

- Plastgrommet Accessories

- PLASTGrommet Bull Rack 1620

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet BullRack Cutter

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- Swivel Rack

- PLASTGrommet Compact Lifter

- PLASTGrommet Compact e- Lifter Lite

- PLASTGrommet Quick Lifter

- Printers

-

Cutting

-

Laminators

-

Finishing

- Eyelet Machines

- Plastrommet Semi-automatic Queen & SpeedQueen

- Plastgrommet Crossover

- Plastgrommet Evolution Automatic eyeleter

- Plastgrommet Autocross Automatic

- Plastgrommet Multipress Automatic

- Plastgrommet Finishing Station

- Plastgrommet Roll2Roll Lite

- Plastgrommet All in One

- Plastgrommet Clear Plastic Recyclable Eyelets

- Plastgrommet Roll to Roll Pro

- Sewing Machines

- Matic CRONOS GO

- Matic CRONOS SEWING SYSTEM

- Matic CRONOS 4.0

- Matic Nyx Overlock

- Matic Nyx Ultimate Curtain Sewing System

- Matic ORION SEWING SYSTEM

- Matic Hercules Awning Sewing System

- Matic Nyx Compact

- Matic Nyx Top Tape Sewing System

- Matic Nyx Roman

- Recyclable Thread

- Recyclable Keder SRK

- Cotton Cones Dual purpose

- Cotton bonded nylon

- White Keder

- Translucent Blue Keder

- Self Adhesive Recyclable

- Silicon Keder

- Hammer In Keder Silver

- Hammer in Keder Clear

-

Racks & Lifters

- Plastgrommet Media Handling

- PLASTGrommet Compact Lifter

- PLASTGrommet Bull Rack 1620

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet BullRack Cutter

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- PLASTGrommet Compact e- Lifter Lite

- PLASTgommet e-lifter Pro

- PLASTgrommet Roll Clips

- Used & Ex-Dem

- Cutting Mats & Tools