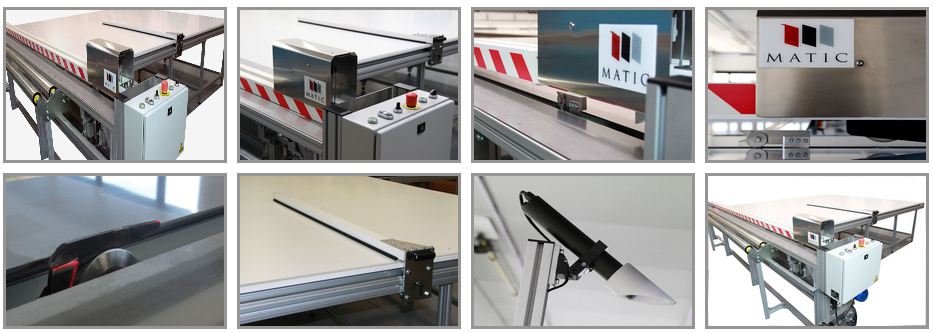

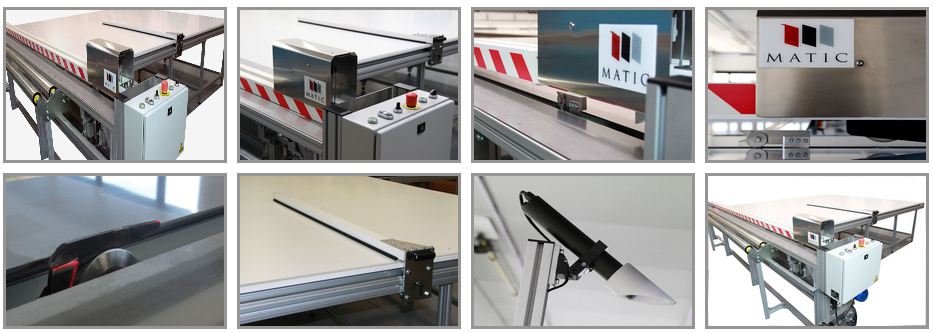

The FLEXICUT is a semi-automatic linear cutter with the versatility of 1 up to 3 cutting tools:

The FLEXICUT is a semi-automatic linear cutter with the versatility of 1 up to 3 cutting tools:

Ultrasonic, Crush Cut and Rotating Knife.

The cutting tools are easily interchangeable with the turn of a switch.

It's design, adaptability and simplicity make the Flexicut one of the most versatile cutting machines on the market.

The Flexicut will butt to your existing table but we recommend the optional table extension.

Flexicut is a “3 tools in 1" cutting machine.

Features

• Different cutting technologies to achieve the highest quality result

• Up to three cutting technologies available in any combination

- Ultrasonic: for textile fabrics, cutting and sealing the edge to avoid fraying

- Crush Cut: for glass fibre coated with PVC in order to avoid fraying

- Rotating knife: for polyester coated with PVC

Specifications - Cutting tools: ultrasonic, crush cut and rotative knife

- Cutting length: 3.2m, 4m and 5m

- Size of auxiliary table: 3.2m x 3.5m

- Cuts: PVC, screens, black-out, zebra, polyester, coated fabrics, composites and more.

- Air pressure: 8 bar

Features

- Interchangeable cutting tools - Choose 1, 2 or 3 tools: ultrasonic, crush cut and rotating knife.

- Useful cutting: from 3.2m up to 5m

- Variable cutting speed according to each fabric - The operator has full control of speed.

- Double pressure bars - Keeps the fabric stable in place during the cutting process.

- Sensor to detect the end of the fabric - Avoids wear of the cutting tools.

- Automatic opening of the pressure bars at the end of the cutting cycle.

- Automatic return of the cutting tools to start position.

- Motorised roll unwinding*

- Automatic winding device to roll up the textile.*

- Auxiliary table with manual stop bar for positioning and measuring*

Advantages - Ideal for the production of: roller blinds, awnings, curtains, and more.

- Flexicut can be adapted to an existing work table.

- Automatic movement of the cutting tools is faster and more precise than manual cutting.

- Fewer chances of human errors with automation

- The interchangeable cutting tools make it a flexible and versatile machine

- Easy and safe to use by everyone - even a non-skilled operator.

- No measuring needed, measuring tape and stop edge included on the optional auxiliary table.

- Low cost of operation and maintenance.

*Optional

The FLEXICUT is a semi-automatic linear cutter with the versatility of 1 up to 3 cutting tools:

The FLEXICUT is a semi-automatic linear cutter with the versatility of 1 up to 3 cutting tools: